Product description

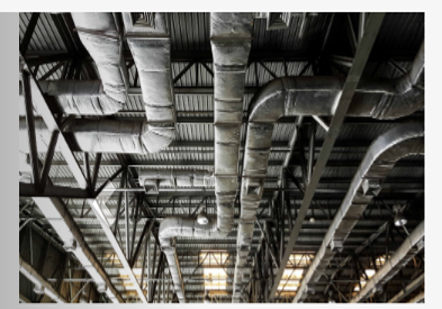

* Cable tray ladder is a useful tool that not only brings savings but also forms and ensures high security for buildings, high-rise hospitals, factories… Cable ladder (also known as electric ladder, cable tray ladder or cable ladder) is a guide ladder used for the installation of wires and cables in buildings, factories, apartments, buildings… Cable trays (also known as electrical trays or trunking trays) are conductors used for the installation of wires and cables in factories, apartments, buildings… Cable tray ladder is a useful tool that not only brings savings but also forms and ensures high security for buildings, high-rise hospitals, factories… Advantages of using cable tray ladders The electric chute ladder helps to protect the safety of cables and construction workers, eliminating the risk of tearing or scratching the surface in the trough as well as causing no injury to the contractor. Especially cable ladders also reduce installation time. The shape of the electric ladder and the electric tray is very basic and solid, so it is convenient to transport in the construction site. Construction tools only need steel cutting pliers, screwdrivers and screwdrivers. Extensive cable ladder accessories, convenient assembly and manual execution reduce construction time. It is advisable to ensure that the installation work of the tray system is carried out properly and legally to be able to bring into full play all the functions and advantages of the cable carrier.

VTSAuto has several cable tray buying guides to help you with the best cable tray buying skills:

1. Choose the type of cable tray that best meets your requirements as well as your economic ability. Cable trays with holes (Trays) are designed with ventilation holes according to customer requirements. This type of cable tray is typically used for applications where medium temperature limits are not allowed.

2. Select the material as well as the outer coating of the cable tray. Because most cable trays will be used in outdoor environments, you should choose the type of material as well as the exterior paint that is suitable for the environment where your cable tray system is installed.

– Hot-dip galvanized cable trays can be used in many different climatic conditions, so in practice they are often used to protect cables in many locations with different climatic conditions.

Non-galvanized cable trays are commonly used for indoor applications

Cable trays made of steel are high cost cable trays especially used in the food industry and the petrochemical industry. This type of cable tray is usually protected by a black plastic layer.

– Powder coated cable tray is a type of cable tray that is protected by a layer of paint using traditional spray painting technologies.

3. Limiting the cable protection capacity of cable tray system depends on how to choose the appropriate thickness and height of cable tray. To choose the right cable tray, consider the distance between the support cable trays.

4. Determining the edge height is also very important, in the catalog this size will be specified (40, 48, 60, 75, 100, 150). These dimensions will change according to the load of the cable tray to match the cable support standards of the cable trays.

– Cable lines will be installed in advance (so it is necessary to equip with knowledge about construction structure and install machinery and equipment)

– Be aware of possible cable tray height requirements to match the total tonnage of the cable system

– The height and width of the cable tray should be suitable for the load of the selected cable type. Choosing the right size cable tray ladder is very important.

5. Different types of cable trays will have different width sizes. If necessary, specify the exact width of the cable tray appropriate to the cable management.

6. Radius of cable trunking, usually people will use the minimum radius of the cable [permissible rating].

If you have any further questions , do not hesitate to contact us:

OFFICE & FACTORY

No.2 Street, Bien Hoa 1 Industrial Zone, Bien Hoa city, Dong Nai, Vietnam

(+84) (0) 251 3832 382

(+84) (0) 933 378 785

Email: info@vtsauto.vn

Website: www.auravina.com

Reviews

There are no reviews yet.